end wall flashing detail

Using a pencil or a sharpie mark where the flashing and gable meet. How To Install Foam Closures For Endwall Flashing 1.

Eave Soffit Vent Google Search Construction Documents Metal Roof Construction Gutters

Hyload Headquarters 5020 Enterprise Parkway Seville Ohio 44273 Email.

. The pan flashing has end dams at the sides to prevent water from moving. Flashing should overlap the roof-covering material but on asphalt shingle roofs for aesthetic reasons the part of the headwall flashing that extends down over asphalt shingles is often covered with a course of shingle tabs. For front end-walls where roofing shingles meet siding the metal flashing strip should be bent using a metal brake to extend at least 2 inches up the vertical wall and at least 3 inches onto the last shingle course.

Adjacent pieces are lapped at least 6 and sealed see Solder and Sealants section for sealant recommendations. Wall To Roof Flashing For Non-Wall Supported Deck Typical - PG-LS-WALL-01. Inspect the wall and roof framing to assess existing conditions and develop specific detailing for flashing the intersection of the wall and roof.

The pan flashing surface is a durable waterproof material that provides a continuous water barrier without holes tears or wrinkles that could retain water in the opening. Typical Flashing Joint and End Dam. Certain components as depicted in these details may not be provided by the roofing contractor.

330 769-3546 Toll Free. For chimneys specifically base flashing is the first of two types of flashing applied and sits below the second type of flashing counter flashing. Wherever long runs of copper flashing are required multiple sheets of copper flashing are used.

The cap flashing is then locked over the edge strips. Additional fixing may need to be considered in wind-exposed locations eg. Leave approximately one inch past the edge of the gable trim on both ends of the flashing.

Its placed behind the wall steel and on. Pre-flashing the coping-to-wall termination with membrane flashing eg. Continuous wood blocking is first securely anchored to the top of the masonry and covered by a layer of building paper.

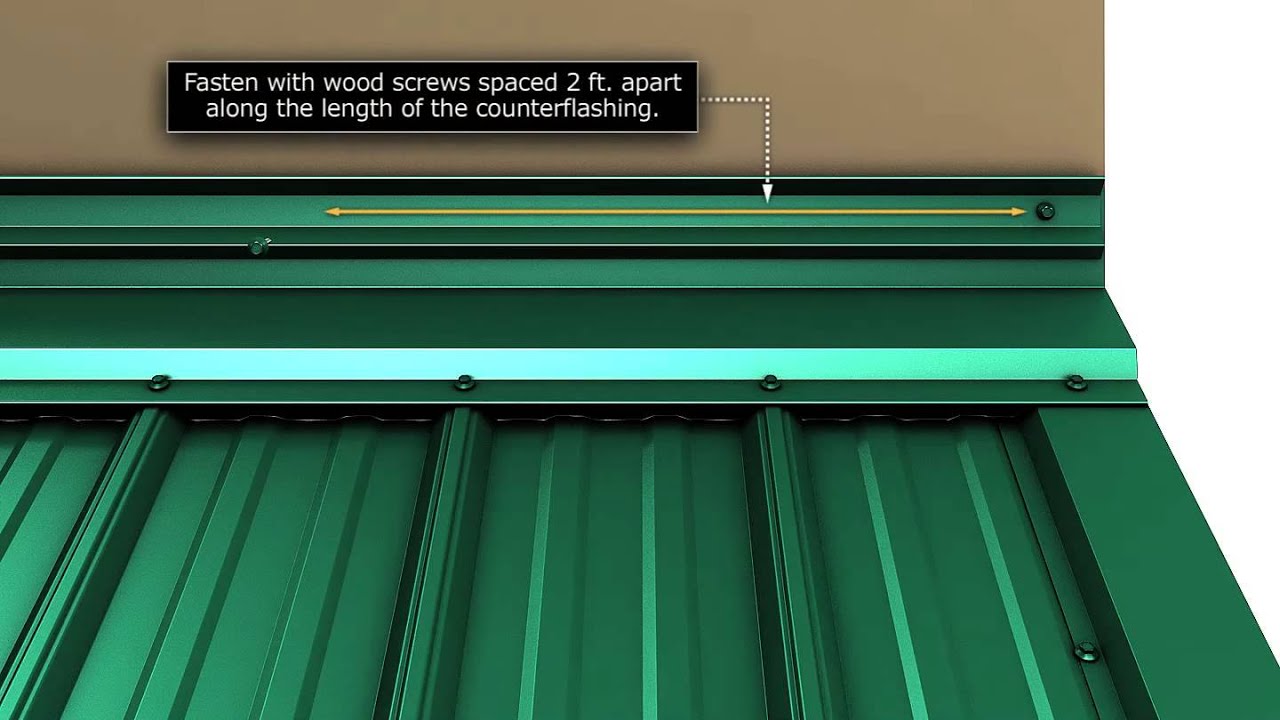

If there is no metal flashing installed at the wall-roof intersection or if the existing flashing is damaged improperly installed or allowing water to damage the wall remove the siding and any existing flashing to expose at least 8 inches of the. Prior to fastening your endwall double sided butyl tape should be placed 1 from the edge of the endwall. Fasteners close to folded edges generally cause the least distortion.

Request DWG File for PG-LS-WALL-03-2D. Flashing edges beneath cladding normally only require nominal attachment to battens. The detail illustrates a copper cap flashing installed over a masonry wall.

Place the foam closure strips. At the ends the flashing is detailed as shown to provide an effective dam preventing moisture from draining back into the. Equipment Curb Detail - PG-LS-CURB-02-3D.

Correct detailing of LYSAGHTroof and wall flashing has more than cosmetic importance - it is essential in ensuring the wet weather performance of the cladding. The pan flashing has a back dam or positive slope to direct water to the outside of the wall. 10 Long Length 26 Gauge Metal Matches color of panel Use with OUTSIDE CLOSURES HOW MANY DO I NEED.

Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall. Flashing is generally fixed to cladding or other flashing sections using rivets or self-drilling screws. Then take the flashing off and fold it down where you marked it.

With self-adhering membrane is suggested prior to installation of sheet metal saddle flashing. The lower face of the Through the Wall Z Bar Flashing is extended past the end of the Vertical BlockingBacking Material an inch or two to cover the intersection of the Exterior Wall Covering and the end of the Vertical BlockingBacking Material. Outside Corner Flashing Detail Typical - PG-LS-WALL-03-2D.

From 2420 From 2057. Dont mistake this condition for headwall flashing routed beneath the shingles and call it a defect. By folding down the flashing you keep water from rolling between the top of the gable trim and the end wall flashing.

Correct flashing and detailing will improve the overall appearance of the finished job. Home Trim Endwall Flashing. ADD UP THE TOTAL LINEAR FEET OF ENDWALL NEEDED AND DIVIDE BY 95.

The advice given in this manual is consistent with the requirements of the Building Code of Australia and is aimed at ensuring. Continuous copper edge strips are then fastened to the wood blocking.

Black Metal Roof Porch Architecture Interior Design Guidelines

02 010 0401 Sill Detail Single Wythe Block International Masonry Institute Masonry Roof Detail Roof Siding

Pin On Architectural Construction Details

Pin By End Studio On Porch Ideas Masonry Wall Shingling Roof Maintenance

Pitched Roof To Brick Wall Huse

Pin On Home Diy Hacks Everything Else

Metal Roof Unvented Exterior 6 Rigid Insulation Metal Roof Roof Insulation Rigid Insulation

Parapet Wall To Curtain Wall End Parapet Membrane Roof Curtain Wall

Cathedral Ceiling Ventilation Shed Roof Cathedral Ceiling Roof Repair

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Corrugated Metal Roof